Value Realization

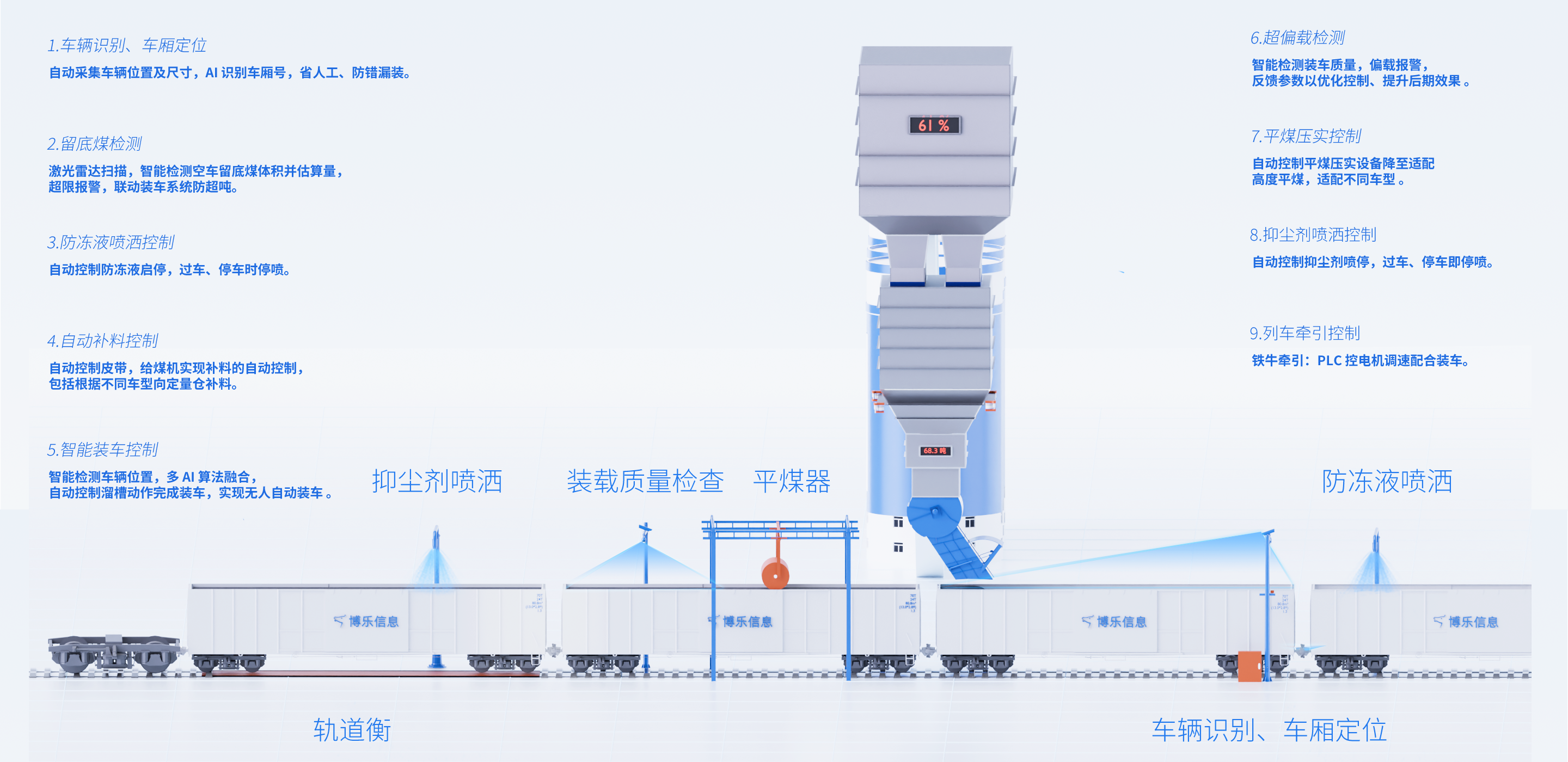

- No blank, no overload, no shortage and no unbalanced load

- Artificial Intelligence (AI) and Equipment Automatic Control

- Laser Radar and Video Intelligent Recognition Technology

- AI Video Recognition Technology and Grating Through-beam Positioning Technology

- Manned patrol, unmanned operation, reduced workers but with high efficiency

- The loading time is reduced from 5h to 2h

- Staffing reduced from 9 persons to 2 persons per shift

- Unbalanced loading rate reduced from 1.5% to 0.5%

Business Function

Cases

Used in transportations of bulk materials in all industries

Choice for 1000+ Leading Clients in the Industry

12 Reasons to Select Us

-

18 years of accumulation

Top 500 cooperation experience

-

IURA collaboration

Supported by elite talents from universities

-

Master's and doctoral R&D

Independent research and development of products

-

Flexible expansion

Strong compatibility and flexible expansion

-

Timeliness guarantee

7*24-hour real-time service

-

Dedicated customer service

Butler-style one-on-one service

-

Personalized customization

Responding to customers' personalized needs

-

Security deployment

Full-cycle safety guarantee

-

95% technology transformation

Accurately identifying customers’ demands

-

Risk plan

Normal operation available even during faults

-

Easy for maintenance

Easy and efficient personnel operation

-

Upgrade service

Phased product upgrades and updates