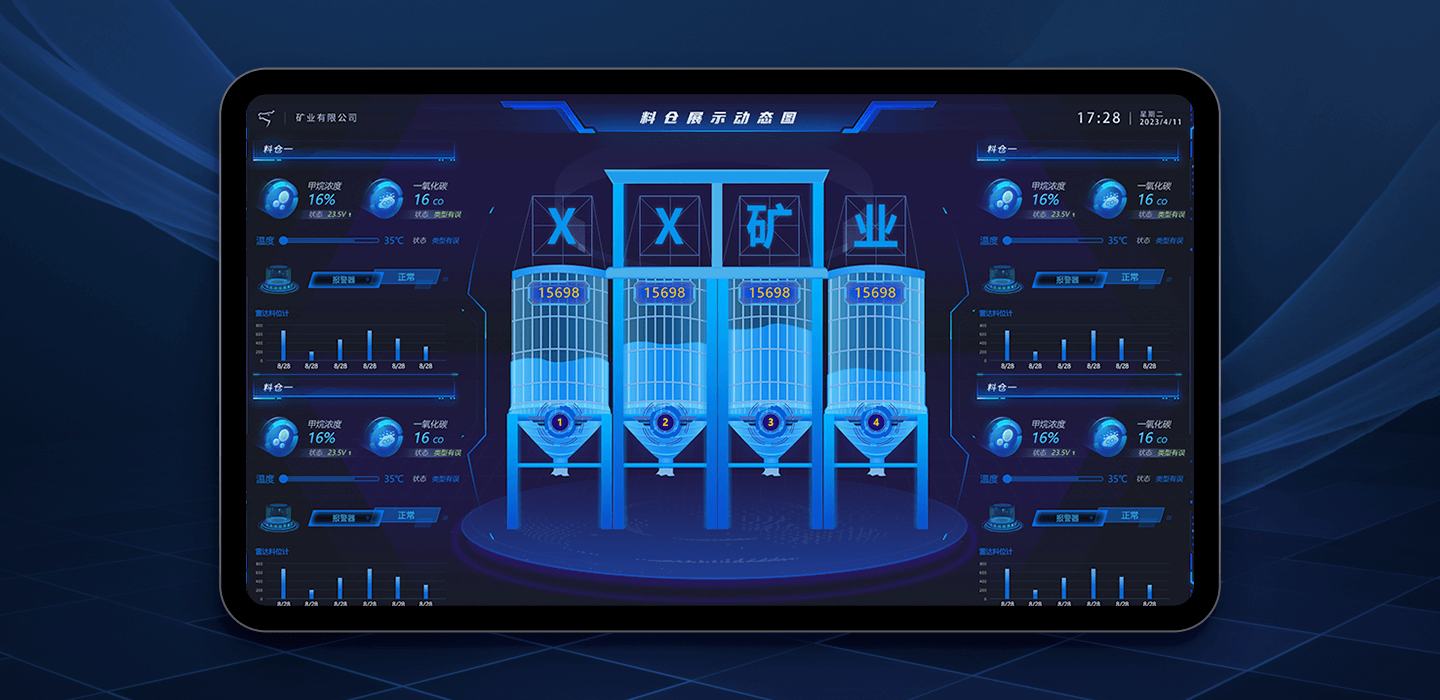

Unmanned Automatic Quantitative Loading in the Whole Process

-

Making Loading Simpler, More Efficient and Safe

- Replace traditional manual work mode, reducing labor cost by 85%

- Scheduled loading + dynamic dispatching, driver waiting time reduced by 80%

- Automatic + intelligent algorithm optimization, daily shipment increased by 3 times +

- Intelligent anti-cheating + precise control to eliminate overload and wrong installation risk

- Automatic operation in the whole process to ensure no persons exposed to high dangers

- Real-time visual monitoring of loading progress, vehicle information and cargo data

- Adaptive environment, stable operation in inclement weather or high dust field

3D radar + AI technology, up to 99.7% accuracy of feeding

Intelligent Cab

Cases

Used in transportations of bulk materials in all industries

Choice for 1000+ Leading Clients in the Industry

12 Reasons to Select Us

-

18 years of accumulation

Top 500 cooperation experience

-

IURA collaboration

Supported by elite talents from universities

-

Master's and doctoral R&D

Independent research and development of products

-

Flexible expansion

Strong compatibility and flexible expansion

-

Timeliness guarantee

7*24-hour real-time service

-

Dedicated customer service

Butler-style one-on-one service

-

Personalized customization

Responding to customers' personalized needs

-

Security deployment

Full-cycle safety guarantee

-

95% technology transformation

Accurately identifying customers’ demands

-

Risk plan

Normal operation available even during faults

-

Easy for maintenance

Easy and efficient personnel operation

-

Upgrade service

Phased product upgrades and updates